Quality Control

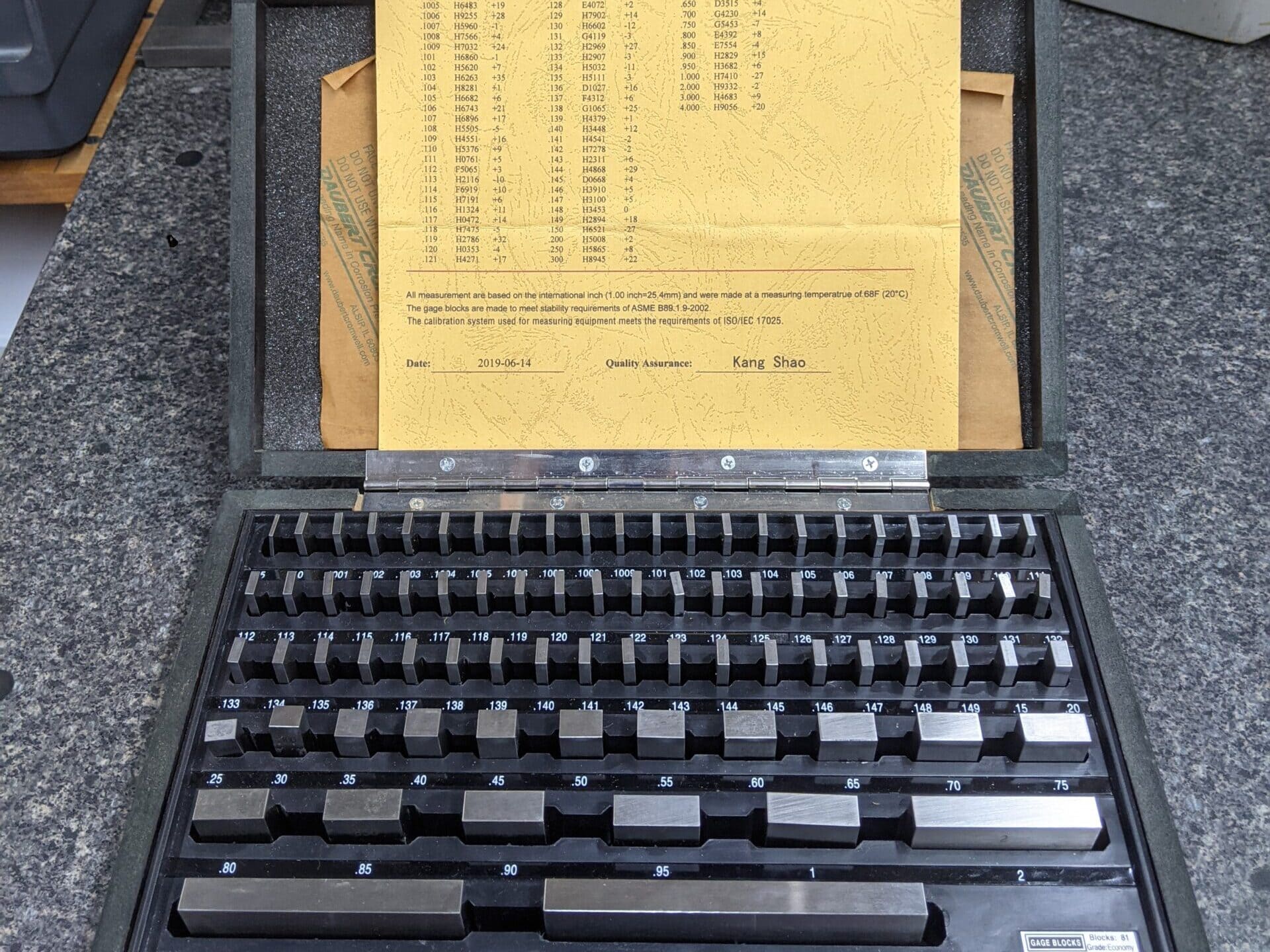

The quality of everything we make means a lot to us. We have a gage to measure just about anything and everything. Everything we make is inspected by the operator and our quality inspector to ensure our parts are kept to the highest standard.

Our inspection equipment includes:

- Calibrated Micro-Hite Manual CMM running PC-DMIS for precision locational data.

- Mitutoyo Micrometers with an accuracy of ±0.00005 as well as an assortment of manual micrometers.

- Mitutoyo Calipers with an accuracy of ±0.0005.

- Calibrated gage pins accurate to each gages class.

- Calibrated A+ gage blocks to calibrate and verify all equipment

- Various drop indicators and depth micrometers including a Mitutoyo digital drop indicator

- Various test indicators including tenth indicators and thousandths indicators

- Calibrated surface plates to always uphold flatness and parallelism.